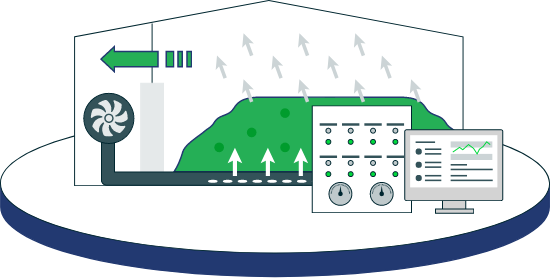

McGill composting facilities are designed to support the proprietary process responsible for the accelerated biodegradation of target compounds.

The modular design and rapid throughput provide a flexible, adaptable, and cost-effective way of turning all kinds of organic waste into premium compost products.